NEWS

Viega products receive Navy approval

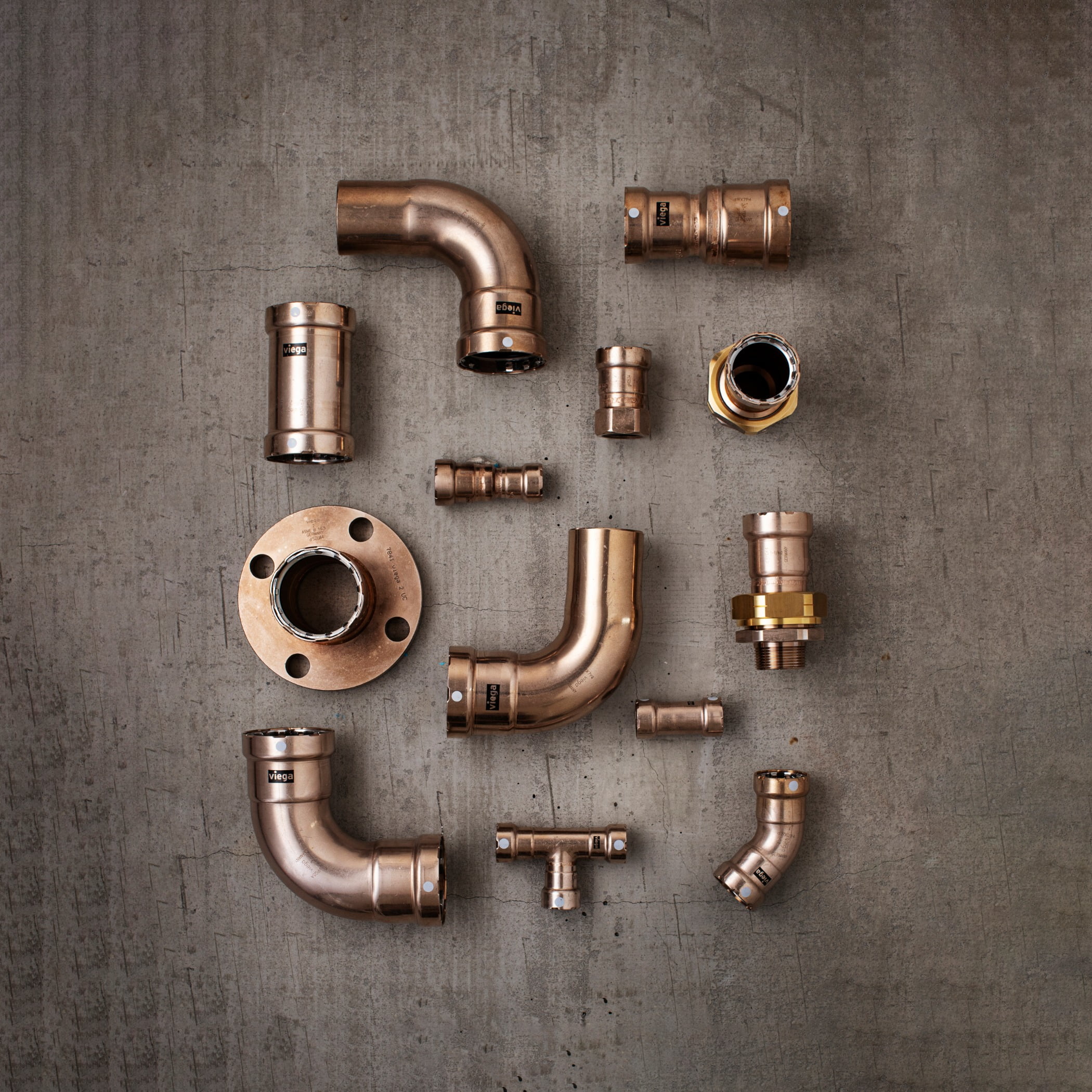

Viega MegaPress CuNi and ProPress copper fittings are the first press fittings approved for use in Navy combat ships.

After years of rigorous testing, the Naval Sea Systems Command (NAVSEA) has approved the use of MegaPress CuNi mechanically attached fittings in sizes 1/2-inch to 2 inches in surface combatants for a variety of systems, including chilled water, potable water, electronic freshwater cooling, seawater cooling, washdown countermeasures, drainage and many others. ProPress copper 1/2-inch fittings were also approved for potable water and various drains.

“NAVSEA is arguably the toughest standard in the world, and earning that approval has been a longtime goal of Viega,” Viega Director of Marine TJ Tracy said. “It’s an affirmation of just how reliable and durable our fittings are in even the most demanding circumstances.”

Pressing pipe offers the Navy, its shipyards and contractors two enormous benefits, Viega noted.

The first is mitigation of fire. Fire is one of the greatest dangers in ship construction, repair and maintenance. There were more than 600 shipboard fires documented between 2017 and 2020. A recent analysis by the Society of Naval Architects and Marine Engineers found more than half of the fires were caused by hot work, such as welding and soldering.

In July 2020, welding sparks ignited small fires on Navy ships at two separate shipyards. Though they were quickly extinguished, the fires prompted work shutdowns while safety measures were reviewed. That same month, the amphibious assault ship Bonhomme Richard burned for four days while pierside in San Diego. Repairs were estimated to take six years and cost $3 billion, so the Navy was forced to decommission the ship 18 years ahead of schedule.

Because pressing does not require heat, flame or an external power source, it eliminates the danger of fire when joining pipe, Viega explained. It also makes it unnecessary to post a fire watch or to prepare a jobsite for hot work.

The second benefit is cost and labor savings, Viega added. Pressing can reduce installation time by 70% over traditional methods of joining pipe, the manufacturer stated. When coupled with savings when testing the systems, due to near zero leaks, the cost and schedule advantages easily outweigh the investment, Viega stated. The National Steel and Shipbuilding Co. (NASSCO), which builds Navy ships, has done studies showing that testing pressed pipe fittings costs less due to fewer leaks, repairs and retesting.

“Viega has been helping commercial marine and other industries benefit from pressing for years, and we’re excited to bring that technology to our defense partners. We’re proud and confident that our fittings will make pipe joining safer, faster and more efficient on Navy ships,” Tracy said.

The primary NAVSEA-approved fitting is MegaPress CuNi, a 90/10 copper nickel alloy specifically designed to withstand harsh marine environments. It can be used on Schedule 40 and Class 200 90/10 copper nickel pipe. The second is the ProPress copper fitting system, which offers more than 400 different configurations and three different sealing elements: EPDM, FKM and HNBR.

The Navy approval is only the latest marine-related approval for Viega products. The U.S. Coast Guard, American Bureau of Shipping, DNV-GL, Lloyd’s Register, Bureau Veritas and RINA all have previously approved the use of Viega fittings in marine environments.

Dewberry acquires Edmonds Engineering

Dewberry, a privately held professional services firm, announced the acquisition of Edmonds Engineering. The 75-plus person firm has five locations with offices in Alabama, Mississippi and Tennessee, with its headquarters located in Birmingham, Alabama.

“Our immediate comradery and strategic alignment are two of the many reasons why Edmonds Engineering is excited to join Dewberry. This will allow us to provide resources from a national firm with expertise across the U.S. and encompassing many markets and services,” Edmonds Engineering CEO Dan Blackman, P.E. said. “We anticipate business as normal with our leadership and project staff in place with outstanding opportunities for our staff to have improved access to training and development programs, an expanded knowledge base, and project diversity, which we will leverage in support of our clients and continue our culture of execution.”

“As a family-owned, client-centric and community-driven firm, we believe that welcoming Edmonds Engineering into Dewberry is a strategic move that will allow us all to better serve our clients, given that both organizations have similar values and goals,” Dewberry Executive Chairman of the Board Barry K. Dewberry said.

As Dewberry | Edmonds, the firm’s existing leadership will continue to lead operations across the various Alabama, Mississippi, and Tennessee offices, delivering quality services to their clients, Dewberry added.

ASC Engineered Solutions acquires Trenton Pipe Nipple

ASC Engineered Solutions has acquired Federalsburg, Maryland-based Trenton Pipe Nipple Co. Trenton Pipe Nipple Co. produces and supplies brass and stainless nipples, fittings and pipe to industrial pipe, valve and fittings markets. In addition, the company’s custom fabrication capabilities will enable ASC Engineered Solutions to handle special customer requests for certain pipe nipples.

ASC Engineered Solutions’ CEO Jason Hild said, “We expect that the addition of Trenton Pipe Nipple will strengthen our organization’s ability to provide differentiated solutions to our customers.”

“We are excited to have the additional product breadth, knowledgeable team members and distribution partners that Trenton Pipe Nipple brings to us,” said Dean Taylor, ASC Engineered Solutions executive vice president. “I would personally like to thank Steve Holloway, past owner of Trenton, for his dedication to our industry and wish him well as he transitions into retirement. Steve will provide consultative support through the integration.”

KAI Enterprises earns top honor

KAI Enterprises has been awarded a Top Workplace 2021 honor by The St. Louis Post-Dispatch Top Workplaces. The list is based solely on employee feedback gathered through a third-party survey administered by employee engagement technology partner Energage. The anonymous survey uniquely measures 15 culture drivers that are critical to the success of any organization including alignment, execution, and connection, KAI explained.

KAI was selected among hundreds of companies in the Greater St. Louis area. This is KAI’s first time receiving the award from The St. Louis Post-Dispatch Top Workplaces. The selected companies are featured in its June 17 issue.

“KAI’s selection as a Top St. Louis Workplace is a wonderful public acknowledgement of the company culture we sought to establish and maintain,” KAI Managing Partner Brad Simmons, FAIA said. “The real recognition goes 100% to all the KAI employees who supported this endorsement of the work environment we are promoting. We appreciate all they do daily to uphold our KAI core values and business mission of transforming communities. Our goal is to continue to provide the work platform, employee amenities and inclusive environment that fosters a preferred employment setting — where everyone can succeed and excel.”

The majority of KAI’s St. Louis-based employees participated in the survey. KAI employs a diverse team of architects, engineers, interior designers, builders and support staff at its headquarters in St. Louis and offices in Dallas-Fort Worth; Kansas City, Kansas; and Atlanta, with additional project offices throughout the U.S. The firm specializes in residential, commercial, K-12, higher education, health care, science and technology, aviation, mobility, sports and entertainment, government, water and community-focused projects.

ASHRAE releases Standard 62.1 User’s Manual

ASHRAE has released the 2019 edition of the Standard 62.1 User’s Manual. The latest 62.1 User’s Manual focuses on ASHRAE’s primary ventilation standard, ANSI/ASHRAE Standard 62.1-2019.

The publication was created to be used alongside ANSI/ASHRAE Standard 62.1-2019 and explains how to apply the criteria set out by the standard, by providing examples, sample calculations and best practices for professionals concerned with ventilation and indoor air quality in nonresidential buildings.

“The user’s manual assists in the design, installation, and operation of buildings in accordance with Standard 62.1-2019,” said Wayne Thomann, chair of Standard 62.1 Project Monitoring Subcommittee. “It is important to remember that Standard 62.1 is written to be code enforceable, and therefore contains only mandatory language, while the user’s manual paraphrases and explains the requirements, making it a valuable resource for both the architects and engineers designing the building and those responsible for constructing, operating and maintaining the building. The user’s manual facilitates compliance with the performance requirements defined in the standard.”

The user’s manual is intended to support building professionals, including architects, engineers, manufacturers, plan examiners, field inspectors, general and specialty contractors and operation and maintenance personnel. The publication offers crucial supplement for professionals concerned with ventilation and indoor air quality.

To purchase the Standard 62.1 User’s Manual, visit the ASHRAE Bookstore or contact ASHRAE Customer Service by phone at 1-800-527-4723 (United States and Canada), 404-636-8400 (worldwide).