a hole in one

High-efficiency water heaters score

Water heater retrofit helps growing Alabama country club meet increasing demand.

By Peter Mosher

In 2018, Wynlakes Golf & Country Club facilities staff began recognizing the shortcomings of an older, inefficient water heating system.

Montgomery, Alabama-based Wynlakes Golf & Country Club offers far more than golf, tennis and fine dining. With yearly membership on the rise and a growing list of accommodations — including a full-service salon, massage treatments and even a water park — there is no shortage of opportunities for member enjoyment, and each requires hot water to be ready when it’s needed. In 2018, the club’s facilities staff began recognizing the shortcomings of an older, inefficient water heating system.

Due to their age and sediment buildup, the two 18 year old standard gas water heaters were not as efficient as they could be, requiring additional servicing and expense. These aged units also lacked in their capacity to meet the club’s growing hot water demands, resulting in occasional issues during peak periods.

It was a tough hole to play, but Rheem’s Triton high-efficiency commercial gas water heaters cored a hole-in-one.

Built-in BACnet port easily connects to building management systems with Rheem's Triton commercial water heater.”

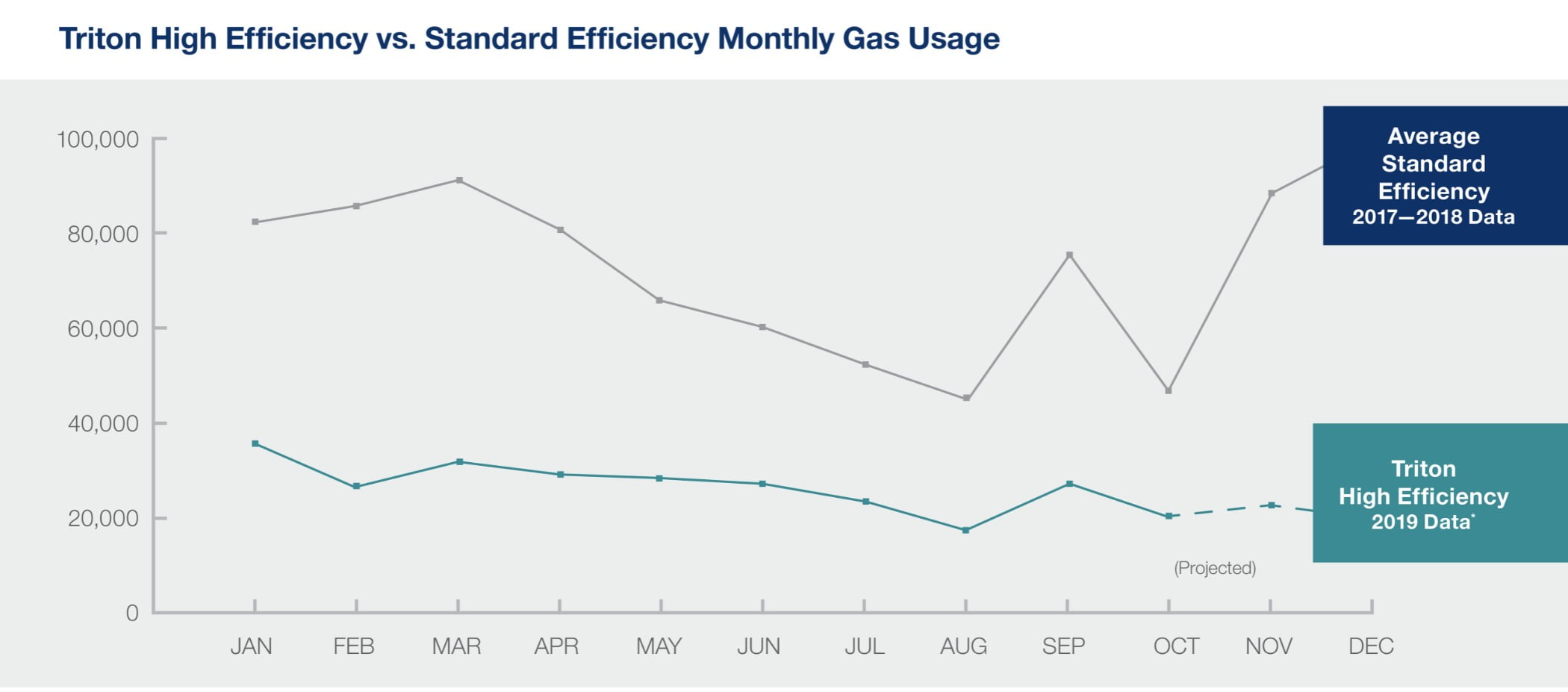

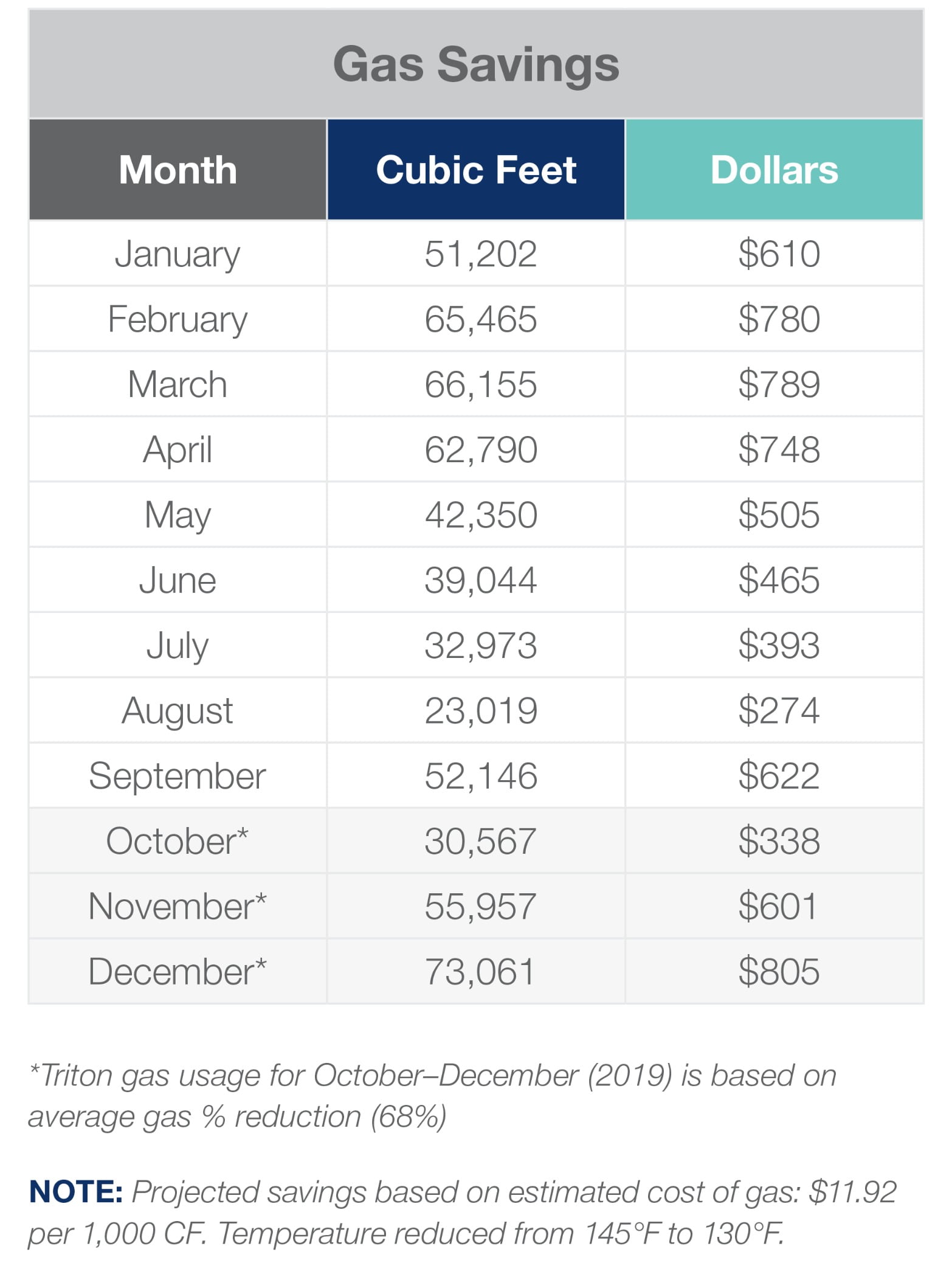

The new Triton units cut gas costs by 66%, saving just under $7,000 in the first year of operation.

The solution

Wynlakes Golf & Country Club selected two 100-gallon Rheem Triton high-efficiency commercial gas water heaters to meet and exceed the facility’s hot-water demand.

“We have used Rheem water heaters on other sites for the other commercial buildings and were really impressed with the reliability and energy cost savings,” says Kelly Dean, facility manager at Wynlakes Golf and Country Club. “When using Rheem, we don’t need to worry if there will be hot water, because there will be. The Rheem water heaters always satisfy our needs during the peak hot water consumption periods.”

Dean notes Rheem helped the facility team go through the proper channels to find what suited their needs best, and who can get the job done right.

ENLARGE

“Working with Rheem’s customer service has always been a pleasure,” he says. “From answering our questions, narrowing down what product will fulfill our needs and installment, it was a pleasurable process for a sometimes tough job.”

Boasting a 97% thermal efficiency — significantly higher than standard water heaters — the new Triton units cut gas costs by 66%, saving just under $7,000 in the first year of operation. That’s a monthly savings of $583. The result is a calculated payback when compared to like-for-like replacement of the existing standard gas units of 2.4 years (assuming the standard gas tank installation is an average of $4,000).

“The entire installation of the water heaters went real smooth — smoother than most,” says R. Garrett Taylor of Bradley Plumbing. “The Triton units featured multiple front and back connection options that allowed my team to meet our goal of straightening up all the piping and providing a very clean installation.”

“Our Triton water heaters have been a dream to work,” Dean adds. “In addition to them being very quiet, we haven’t had any maintenance issues, and the energy savings is impeccable!”

Peter Mosher is product management application engineer for Rheem Manufacturing in Roswell, Georgia. He earned his bachelor's degree in mechanical engineering from Gannon University in 2013, and has been working in the plumbing industry for the past eight years. In his current role, he provides his technical expertise in sizing commercial water heaters and heating systems for all different types of applications. He has a strong focus in providing product solutions that help save energy and conserve water.