What you don’t pay for

Understanding the alphabet soup of energy ratings.

RENEWABLE HEATING DESIGN || By John Siegenthaler, P.E.

RENEWABLE HEATING DESIGN

|| By John Siegenthaler, P.E.

RENEWABLE HEATING DESIGN || By John Siegenthaler, P.E.

Heat pumps move heat from low-temperature sources to higher temperature loads. There are many types of heat pumps, but they all perform this basic thermodynamic mission.

For heating buildings, the low-temperature heat typically comes from outside air, buried earth loops or groundwater. For cooling buildings, the low-grade heat comes from interior air.

Dedicated purpose heat pumps are also used for capturing low-temperature heat from wastewater streams, or exhaust air streams, upgrading the temperature of that heat and sending it to a load such as domestic water heating, pool heating or even snow-melting.

What’s in a number?

The measure of a heat pump’s heating performance is called coefficient of performance (COP). It’s just the ratio of useful output divided by required input, where both the output and input are expressed in the same physical units.

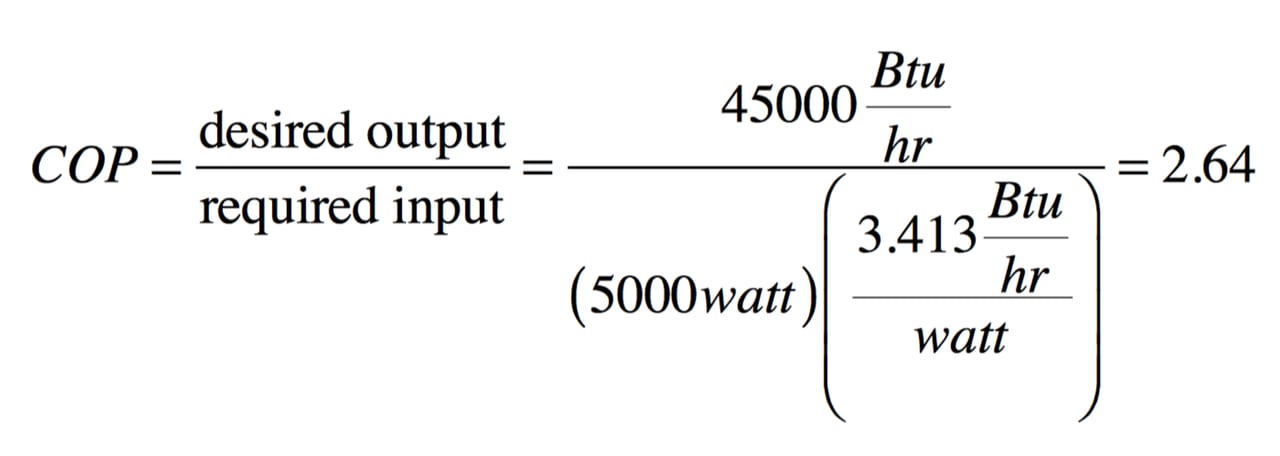

For example, if an air-to-water heat pump delivers 45,000 Btu/h of heat output to a stream of water and has a power input of 5,000 watts, its COP can be determined as follows:

The higher the COP, the greater the desired output is relative to the required input. Thus, higher COPs are always preferred, all other things being equal.

Although higher COPs result in lower electrical energy consumption, it’s important to realize that the person paying the bill for heating a building doesn’t pay for COP. They pay for the Kilowatt•hours (kWh) of electrical energy necessary to run the heat pump. This is an important distinction, and one that’s often misinterpreted when evaluating the merit of one heat pump versus another.

So, how is one supposed to evaluate various heat pump options with differing COP information and different installed cost?

Start by understanding that COP can be calculated in several ways. The most common would be: As an instantaneous performance index or as a seasonal average value.

The instantaneous COP of any heat pump is strongly dependent upon all of the following:

- The temperature of the material from which low-temperature heat is being absorbed;

- The temperature of the material to which higher temperature heat is being released;

- The flow rate of the material supplying the low-temperature heat (e.g., air or water) across the heat pump’s condenser; and

- The flow rate of the material absorbing the higher temperature heat (e.g., air or water) across the heat pump’s condenser.

Under favorable conditions, it’s possible to operate just about any heat pump at very impressive COP values. Unfortunately, those ideal conditions seldom exist for long (if ever) in actual installations.

When evaluating seasonal heating cost, it’s important to use a COP that reflects the wide range of operating conditions the heat pump will experience over an entire heating season. These “seasonal average COP” values are not published by heat pump manufacturers because they don’t know what conditions their units will operate under. Still, it’s possible to simulate those conditions using software that factors in either hourly data for outdoor temperature or bin temperature data, and in the case of geothermal heat pumps, algorithms for heat transfer for specified earth loop configurations. Software simulations also have to account for the variations in the heat pump’s heating capacity and COP under all these conditions. In some cases, the simulation may also have to adjust for time-of-use electrical rates. Such rates, where available, can significantly impact the operating cost for heat pumps that operate a high percentage of their total run time under lower “off-peak” rates.

The result of such a simulation would be a reasonable estimate of the heat pump’s seasonal average COP, and that would be the performance index appropriate for making operating cost comparisons.

One versus another

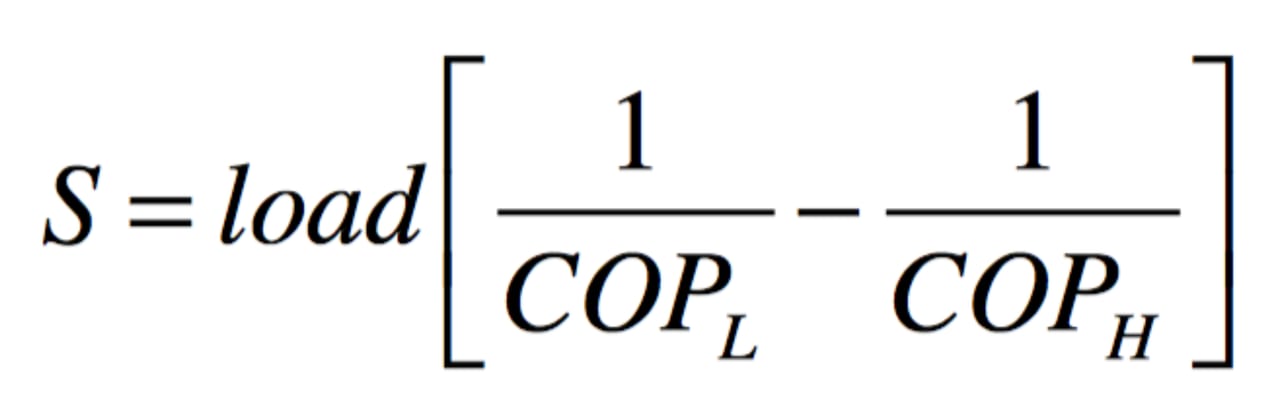

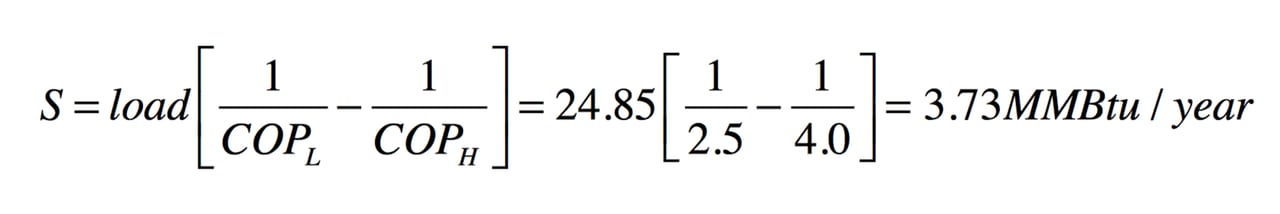

The annual savings in heating energy between two heat pumps with different seasonal average COPs can be estimated using Formula 1.

Where:

S = savings in seasonal heating energy (MMBtu*);

load = total annual heating energy required for the building (MMBtu*);

COPL = seasonal average COP of heat pump having the lower of the two COPs; and

COPH = seasonal average COP of heat pump having the higher of the two COPs.

* 1 MMBtu = 1,000,000 Btu

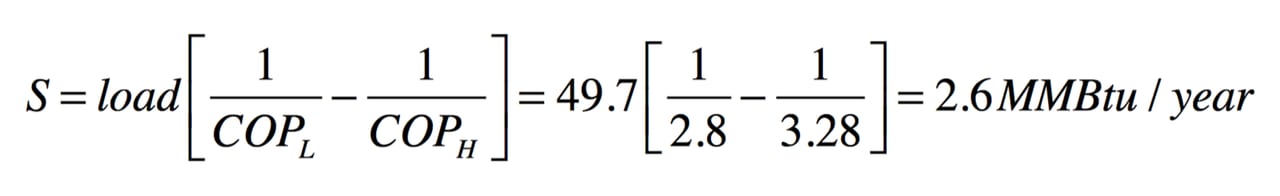

Here’s an example: A house has a design heating load of 36,000 Btu/h when the outdoor temperature is 0° F, and the indoor temperature is 70° F. The house is located in Syracuse, New York, with 6,720 annual heating °F days. The estimated annual space heating energy use is 49.7 MMBtu. Assume that one heat pump option has a seasonal average COP of 3.28. The other heat pump has a seasonal COP of 2.8. Putting these values into Formula 1 yields:

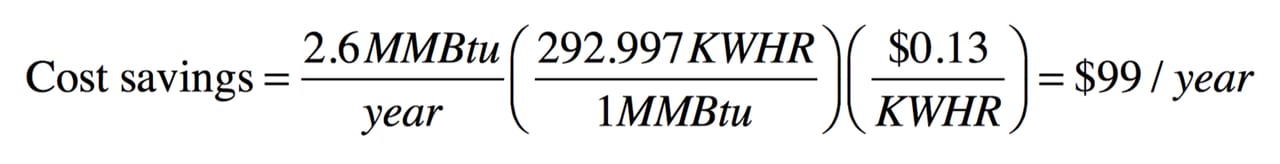

The cost savings associated with an energy savings of 2.6 MMBtu/h depends on the cost of electricity. For example, if electricity sells at a flat rate of $0.13/kWh, the cost savings would be:

Perhaps you’re wondering where the two seasonal average COP values used in this example came from. The seasonal average COPH of 3.28 came from a software simulation of a geothermal water-to-water heat pump supplying warm water to a hydronic radiant panel heating system in the Syracuse house (36,000 Btu/h design load). The radiant panel was assumed to require supply water at 110° under design load conditions. The software used for the simulation was supplied by the heat pump manufacturer.

The seasonal average COPL=2.8 also came from a software simulation. In this case, the software came from a manufacturer of air-to-water heat pumps. This software simulation was also based on the same Syracuse house and the same radiant panel delivery system. Thus, the entire balance of the system downstream of each heat pump was identical, as were the load conditions.

So, based on that last calculation, you’re probably thinking: Can an annual savings of $99 realistically amortize the higher installed cost of the geothermal heat pump within a reasonable time?

The only way to address this is by making an installed cost estimate for both systems, factor in any currently available rebates, and see what the difference would be. Here are the assumed (but nonetheless realistically estimated) values I will use for the comparison.

The geothermal system was assumed to be supplied from earth loops contained in vertical boreholes, which in the upstate New York area, go for about $3,000 per ton of capacity for the borehole, U-tube piping and grouting. The estimated installed cost of the complete earth loop was $11,800. The installed cost estimated for the balance of the system including the heat pump, circulators, loop fluid, piping, etc., (but excluding the radiant panel heat delivery system — since it would be the same for both heat pumps) was $8,750.

The currently available 26% federal income tax credit was applied to the earth loop and balance of system cost (but not to the distribution system). It comes to a deduction of $5,343. This lowers the net installed cost of the geothermal system (excluding distribution) to $15,207.

The estimated installed cost of the air-to-water system (again excluding the distribution system) was $10,600. There are no currently available federal tax credits for air-to-water heat pumps, and no other deductions were assumed.

The difference in net installed cost between these two systems would be $15,207-$10,600 = $4,607.

So the simple payback of the geothermal heat pump relative to the air-to-water heat pump, based on all the above estimates and assumptions, and assuming no change in electrical cost is $4,607/$99 = 46.5 years. You decide if that’s acceptable.

The current 26% federal tax credits on residential geothermal heat pump installations will remain in place during 2022, and reduce to 22% for 2023. After that, it’s anybody's guess as to what might happen based on the sausage-making process in Washington. As it currently stands, there will be no federal income tax credits for geothermal heat pump installations for 2024 and beyond. That would push the simple payback on the example described above to just about 100 years. Politely stated — this is a difficult scenario to justify.

Shrinking loads

As energy codes become more stringent and the market for low energy buildings, net-zero buildings and the like increases, the energy savings associated with different COP values decreases in direct proportion to the annual space heating energy use. That’s evident from Formula 1. Cut the load in half, and the savings are cut in half. Thus the savings associated with a high-performance heat pump yielding a seasonal average COP of 4.0 versus one with a seasonal COP of say 2.5, in a building with a design load of only 18,000 Btu/h, in Syracuse would be:

At a going rate of $0.13 per kWh, the annual savings would be about $142 per year. That’s almost trivial in comparison to what many households now spend for phone, television and internet. It’s something to think about when contemplating a very high-performance and very pricey heat pump system for a low-energy house. The cocktail party bragging rights are there, but the economic case is simply “unsustainable.”

The bottom Line

COPs, like AFUE values for boilers, and SEER ratings for air conditioners are often preeminently put forth as values to get excited about. That’s OK, but hopefully, you’re convinced that energy cost savings is ultimately what matters.

Tippapatt/iStock/Getty Images Plusvia Getty Images.

John Siegenthaler, P.E., is a consulting engineer and principal of Appropriate Designs, in Holland Patent, New York. In partnership with HeatSpring, he has developed several online courses that provide in-depth design-level training in modern hydronic systems, air-to-water heat pumps and biomass boiler systems. Additional information and resources for hydronic system design are available on Siegenthaler's website at www.hydronicpros.com.