AI, prefabrication help engineers streamline designs.

By Nicole Krawcke

An employee from Autodesk customer, Mechanical Inc, uses Revit and partner GTP Stratus software for prefabrication. Autodesk customers, Chicago Pipefitters Local 597 and Mechanical Inc., use Revit and BIM 360 to streamline prefabrication and gain new efficiencies in the office, shop and the field.

The rapidly evolving software segment for the MEP industry continues to enhance engineers’ designs with more details and collaboration than ever before.

“Technology is moving the engineers to the frontline of design,” says Christoph Lohr, P.E., CPD, ASSE 12080, vice president of strategic initiatives for IAPMO. “Over the past 10 years, many CAD drafters’ duties are being moved to engineers, while ‘the drafter’ has morphed into almost a new discipline entirely — the ‘BIM Department.’ This is aligned with the general trend in other industries that all knowledge work is becoming more specialized. In the case of engineering consulting, the trend appears to be the specialization of HVAC, electrical, plumbing, fire protection, technology and now BIM into separate departments.”

Kyle Seyler, senior product marketing manager at Autodesk, notes that when engineers use a common data environment, they’re able to identify and solve issues faster and with greater accountability across teams.

“For example, Revit cloud worksharing enables multiple designers or engineers to work together in one virtual space,” he says. “Teams can package, share, and aggregate models across disciplines to find issues earlier in the project lifecycle. Catching these issues early on then reduces total cost from rework by resolving issues digitally instead of physically on site.”

Seyler also points out that clash detection is now easily accessible to MEP engineers. “Traditionally, BIM managers with a lot of experience would use Navisworks to surface clashes by setting up clash tests and sharing out the results,” he adds. “Now, with truly automatic clash detection, anyone on the project team can use simple tools like tolerance filters and grouping by property to find the clashes relevant to them, create an issue or mark a batch of clashes as 'not an issue.' This means that work historically done by just one or two people can be spread across multiple people, speeding up coordination and allowing the BIM manager to focus their Navisworks expertise on more complex issues.”

Additionally, MEP software is beginning to see influences from Artificial Intelligence (AI) technology.

Miller Electric team reviews Revit model on a tablet in advance of fabrication.

“We’re already seeing some AI when you think about some of the solutions we build such as Trimble SysQue, which is detailing software engineers and contractors use on top of the Autodesk platform,” notes Chris Peppler, category general manager, building pre-construction software at Trimble. “We believe that AI is going to eventually be able to do 80% to 90% of the modeling of a building. If you think about automated routing and automated placement of valves, pumps and the entire routing of entire pipe systems. AI should be able to give us the ability to automate a lot of that design, which will dramatically impact contractors and engineers just from a workflow standpoint. They also struggle to even find detailers and people to model this stuff, so that could dramatically impact their businesses in a positive way.”

Much of the technology needed to implement automation is already available right now, Peppler points out, but realistically, the MEP industry won’t reach a tipping point of use for another five to 10 years, at least. “It is one thing to prove that it works. It’s another thing for a human to trust it. And that's not just a construction problem. I think it relates to any human being that's being told a computer said this was right. It's going to take some time. And then, there’s the resistance in the construction industry toward adopting technology as fast as other industries do. So I'd say at least 10 years before automation is widely adopted.”

Garrett Jones, segment marketing manager, specialty contractors at Autodesk, says he is already seeing the impact of AI in the design space with the use of generative design.

“It lets designers or engineers input design goals into the software, as well as input constraints such as material, weight, size or cost,” he says. “Then the technology will explore all possible permutations to find the right solution. This approach will help the plumbing and mechanical design teams discover new ways of creating their systems for a building, allowing them to minimize material and labor costs while maintaining the standards set by the owner or general contractor."

Miller Electric engineer uses Revit and LayoutFAST Revit plugin to design and detail electrical model.

Software design trends taking shape

According to Peppler, some of the most prominent trends in the industry are moving toward a better understanding of the supply chain availability and the impact it has on the dramatic increase in prefabrication.

“It’s not only material issues either, it’s labor shortages, which most companies in the construction space are realizing they can’t solve with people on the job site, so they have to solve that through more manufacturing methods and prefabrication. Trimble has been focusing more on prefab and understanding how the supply chain impacts the shop now. You might be modeling something, and then find out it’s not even available. So, it’s important to have quick access to substitutes and supply chain information from a distributor. That’s where a lot of our software is helping right now. We have a solution called Trimble Supplier Xchange, which connects to over 500 distributors. So through using our solutions, people can very quickly understand real-time pricing, real-time availability, and run a lot of scenarios with substitutes and also understand how that impacts their material pricing as well.”

Another trend Peppler points to is the fact that engineers are focused on providing more value to the contractor in today’s market.

“We’ve partnered with a company called KLH Engineers, and what we really like about what they are doing is they’re focused on delivering more value to the contractor and to the project. It's that stereotypical comment that the engineer's model never gets used after that by the contractor. Companies like KLH are realizing they need to change their service offering and provide more value in the model and deliverables and become better partnered with the contractor so that everybody can experience the benefits of high LOD models. KLH is providing tools that automate a lot of the calculations an engineer would do and are putting more details into their models. KLH has done a really nice job of developing an internal toolset that works with Revit as well as with SysQue to bridge that gap.”

According to Seyler, one of the biggest industry trends is the increasing collaboration ability across multiple teams.

“Most challenges can be summarized as poor communication,” he says. “Breakdowns in communication manifest in several ways — design changes made in a silo, unreported issue updates or too much or too little data. These contribute to a drop-off in accountability and trust between teams. A shared environment is the first step to solving these challenges. With a common data environment or smart data federation across organizations, teams can stop worrying about having the most up-to-date files because all data is consistently updated. From there, getting notified about design changes, tracking issue status across multiple products and a shared timeline of events can help solve everything else.

Another top trend impacting the market is designing for prefabrication and the path to industrialized construction, Jones notes.

“This is driven by the need to save time and save money,” he says. “Those two elements are always important, but they’ve become more critical with the labor shortage. If you can reduce the labor hours needed to manufacture and install equipment, you can reduce the impact of the labor shortage on your business. Similarly, prefabrication allows for the predictability of schedule and costs since building elements are manufactured in a controlled environment.”

Additionally, the advancement in prefabrication design has simplified the design process for engineers, Jones adds.

“Traditionally, we’ve seen prefabrication mean a single design used repeatedly to get the benefits of scale,” he says. “Now, we’re seeing a move toward creating a catalog of easily fabricated elements that help create designs to enable easy fabrication. This shift is greatly expanding the types of builds that prefabrication can touch.”

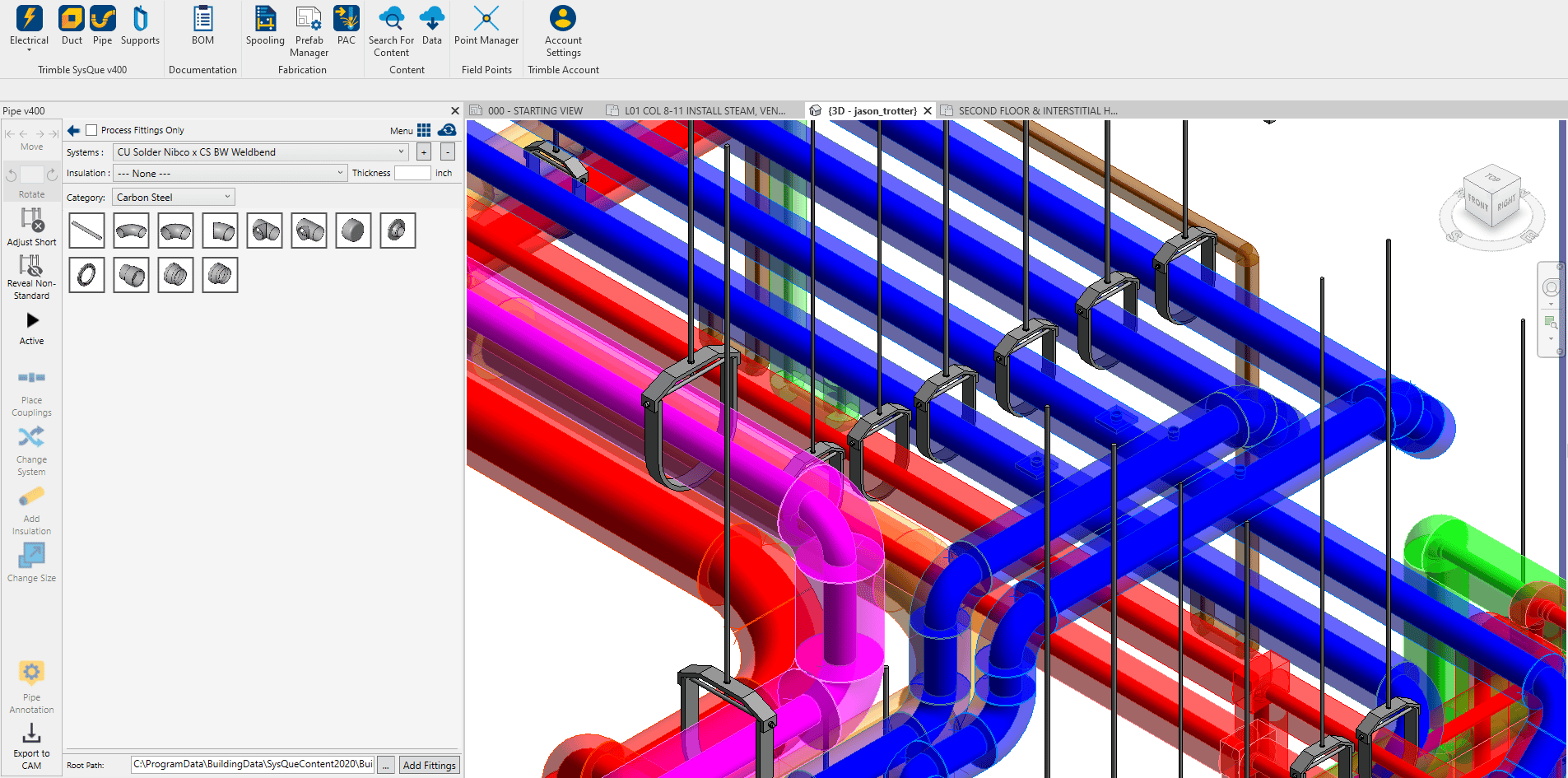

A view of a piping model created with SysQue and Trimble Managed Content. (Trimble managed Pipe, Pipe Fittings and Supports shown).

Changing the game

Every plumbing engineer is familiar with Dr. Roy Hunter, who, back in the 1940s, created Hunter’s Curve, which is used for sizing the plumbing system in a building. The method was used with success until the 1970s, when engineers began to realize that designers were oversizing the pipes. It became clear that a new method was needed, but one wasn’t available until recently with the release of IAPMO’s Water Demand Calculator (WDC).

“Hunter’s Curve has been kind of archaic since the 1970s,” notes Dan Cole, senior director of technical services for IAPMO. “Since the 1970s, there was an international endeavor to try to create a new computational model. A lot of ink was spilled; a lot of academic papers were written, but the codes still kept the old methodology and the pipe sizing continued to be oversized.”

The early stages of the WDC actually began with Cole himself when he worked as a plumbing inspector in the Village of Lake Zurich, Illinois.

“People would come in for permits, and since most of the land here is landlocked, they were building up by adding second floors and new bathrooms. So we’re recalculating all of the fixture units and estimated demand, so I raise the question: ‘What’s your service size?’ In some cases, the service size was only 3/4-inch, but now, they would have to increase it to 1 1/4-inch or 1 1/2-inch with all the newer plumbing fixtures to meet the code. With that increase, the permit cost just went up easily by $50,000. Now, they would have to hire a contractor to dig up their yard, replace the water service and the municipality was going to charge for water service connection and disconnection fees and new water meter fees. So yes, it escalated. This was happening in many jurisdictions, not just mine, and there was an uproar. It actually went to the State department that licenses us, the Illinois Department of Public Health. They had to come up with a new policy on how to address this, which got me thinking about the old method and how it was created.”

Cole began going through Hunter’s extensive research and looking at the math behind it. He even went back to college to take geometry, trigonometry, statistics and calculus classes just so he could understand Hunter’s work.

“Once I was able to recreate Hunter’s work and how he came up with his method and understand it, I knew how to revise it, so that’s what started me on this path,” Cole explains. “I created a report and attended a symposium looking for more engineers to review my research to see if it was valid. One engineer did take it from the Alliance of Water Efficiency, and they were excited about it. So excited that they contacted IAPMO and said, ‘Hey, you need to take a look at this.’ IAMPO then contacted me and asked me to start serving as a committee member and giving presentations on my work. Eventually, they hired me in 2011 to continue doing this research.”

From there, a few ASPE members and the University of Cincinnati also came on board, and after eight years of work, the group put together a new method on how to calculate peak demand for residential buildings, known today as the WDC.

“The significance is huge,” Cole says of using the WDC. “Pipe sizes are being reduced depending on the size of the building. If it's a small residential house with just one bathroom, one kitchen, you probably will be able to reduce it one pipe size diameter. So if a plan review comes in using the old method and it says 1 inch for the water service, it'll probably be reduced to a 3/4-inch water service, which will allow for some significant savings on connection fees and all of that. But as the building gets larger, like a large apartment building, now the water service pipe is being reduced by two to three pipe size diameters and the cost savings is huge.

“The WDC is a more accurate estimation of peak demand, which will help in right-sizing the pipe,” Cole continues. “You don't want the pipe to be too small. Right-sizing a plumbing system will reduce the costs of plumbing material and reduce labor, but even more significantly, it will help with the water quality. If you have oversized pipe and water is not moving through the pipe as it should be, then it becomes stagnant. And when you have stagnant water, it promotes pathogens in the water like Legionella. Water moves through right-sized pipes more frequently, improving water quality.”

While the current WDC tool is specifically for residential buildings, Cole and his group are currently working on a commercial version. They just need enough end-use data of water use in various types of commercial buildings, which they are in the process of gathering.

“Once we have the data, we can put it into calculator and make it work the same way as the residential version,” Cole says.

What’s next?

According to Seyler, MEP engineers will likely see a consolidation of tools in the near future.

“The mounting pressures in labor/training, costs, and owner requirements will drive firms to consolidate to just a few technologies that do a lot more,” he says. “That way, new hires can get onboarded faster with shared tools and reduced manual work, and decision-makers can build consistency and quickly adapt processes from project to project.”

Jones notes that the labor shortage is only going to worsen over the next 10 to 15 years as a large chunk of the workforce retires.

“One of the best ways to keep experienced workers from retiring in the trades is by providing a smooth transition to CAD/VDC departments, and offering easy-to-use and easy-to-understand BIM technology that lessens the learning curve,” he advises.

Peppler notes that Trimble recently released Model Based Estimating in SysQue, which helps engineers understand the entire material and labor cost of the plumbing or mechanical model.

“With one click of a button in SysQue, you can understand the entire material and labor cost of that entire mechanical model,” he says. “Before engineers even get to a point where they hand off a model to a contractor, they should have a good sense for the cost of that model. There’s a lot of benefit in terms of understanding the impact to the project budget upfront.”

Additionally, Peppler points to a big opportunity when it comes to the U.S. MEP software market.

“We see the U.S. market as an opportunity to provide more purpose-built solutions for the MEP engineer,” he says. “By contrast, we have a significant market share in Europe with MEP engineers. Every day engineers in Europe use our solutions to run calculations for them. We see some small, niche software companies that do that in the U.S. However, for Trimble, one of the biggest opportunities we have to help the industry is to bring some of those solutions to the U.S. and to embed the calculations into the modeling software. So if you think about the cooling load calculation that you want to do on a building or the heat loss that you might perceive in the winter — all of that is embedded in our software in Europe. I would say that’s something engineers should also look forward to from Trimble and others in the future.”

Nicole Krawcke, is chief editor of PM Engineer.