Today’s zone controls

No longer your dad’s old relay boards.

By Dan Firkus

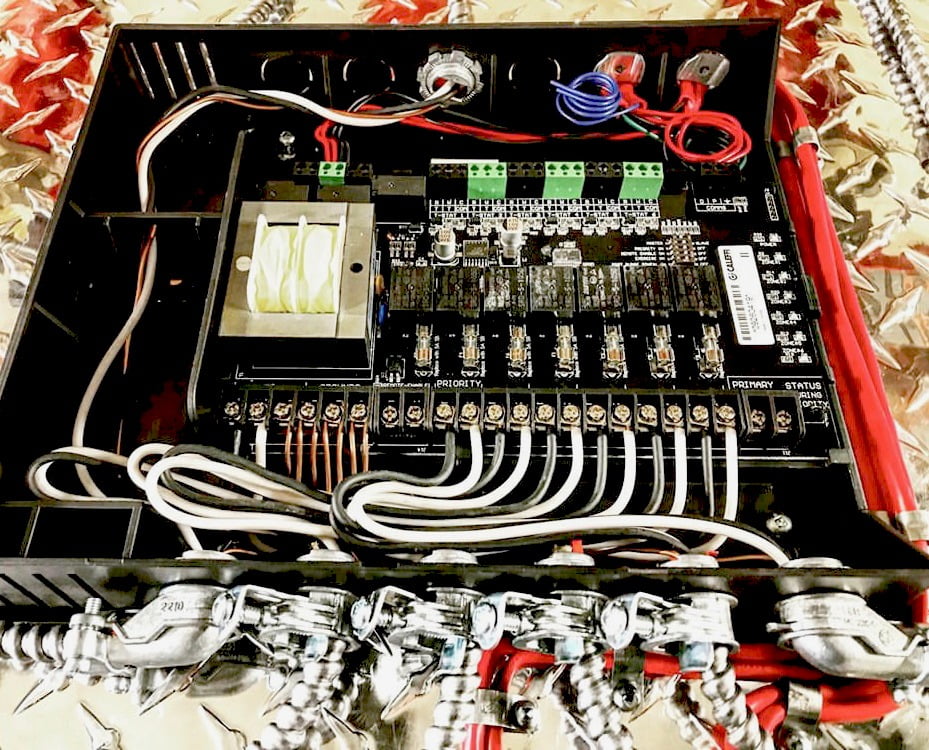

Today’s zone controls have come a long way from the days when controls were literally “relays on a board.” Take a minute to envision the arduous task of assembling the relay board; consider the space required to locate the large number of relays that is common in today’s ever shrinking mechanical spaces. Imagine having to provide power to each relay and combining seemingly endless end-switch wires to control the equipment. All of this could result in hours of troubleshooting if something went wrong. Thankfully, with so many great relay board choices now available, the lives of your customers have become easier.

Relay boards offer myriad friendly capabilities, simplifying installation and service while featuring a clean appearance that compliments the craftsmanship of a professional looking installation. They contain advanced features that engineers appreciate when designing systems that incorporate sophisticated modulating boilers and air to water heat pumps, yet are simple enough to work with basic single-stage, cast iron or mid efficiency boilers. Let’s take a closer look.

Take a minute to envision the arduous task of assembling the relay board; consider the space required to locate the large number of relays that is common in today’s ever shrinking mechanical spaces. Photo courtesy of Caleffi.

Versatile designs, easy installation

Upon opening the box of one of today’s zone relay boards, contractors may be quite impressed with the straight-forward component layout and appreciate the multiple electrical access points that convey a clean, well thought out control design.

A single 120V input power source is all that is needed to power the system. An onboard 120 to 24V transformer powers the low voltage thermostats or zone valves if used. Some models offer capability for adding 24V expansion transformers if additional power is required. The controls pair well with smart thermostats and are also flexible enough to work with a basic mechanical thermostat. To enable the boiler, just a single dry contact end switch relay is used. Some models offer auxiliary dry contact relays and have the ability to control system pumps or secondary pumps.

Safety features such as fuses are commonly provided to protect against field wiring mistakes or electrical overloads on either the high or low voltage side of the control. Some models feature convenient, resettable breakers to protect low voltage components and eliminate the need to have spare fuses available.

There are abundant design options in today’s hydronic systems, thanks to these new controls. Control boards are available in several sizes to accommodate a simple single zone system or a more complex multiple zone system for larger residential or commercial projects. They are advanced enough to allow any number of relay boards be connected together, employing one as a master control and the remaining as add-on subordinate controls. Consequently, the number of zones that can be controlled is unlimited.

There are abundant design options in today’s hydronic systems, thanks to these new controls. Control boards are available in several sizes to accommodate a simple single zone system or a more complex multiple zone system for larger residential or commercial projects. Photo courtesy of Triple H Hydronics.

System designers also have more customized features available, such as a zone valve control with low voltage outputs or a zone pump control with high voltage outputs. A valve zone control can switch and send a 24V power source to any two-wire, three-wire or four-wire zone valve and 120V power to the pumps. The zone pump control can send a 120V power source to all the circulators and all are controlled by heavy duty sealed relays and are fuse protected.

Another popular option is to make one zone a priority. When the prioritized zone calls, the other zones are disabled until the priority zone is satisfied. Some models feature a useful built-in timer for the priority function. For example, the priority zone can be set to timeout after an hour of continuous operation to prevent the other heating zones from falling behind. This option provides a good way of controlling an indirect water heater. To simplify system design, some models offer a separate dry contact end switch that pairs nicely with an advanced modulating boiler and gives the ability to control a pump or zone valve.

Some of the more advanced boards have other features to further aid in system design customization, or maximize system efficiency. Examples are priority post purge and pump exercising. The boards can also provide remote enable, which is a feature to control the zone board application with an incoming 24V or 120V signal. All these features are selectable through onboard dip switches — a very convenient and flexible feature.

Easy troubleshooting

Most of today’s controls include front panel LED lights for function status indication and troubleshooting. Some can also communicate which zone thermostats are calling or even indicate when a zone valve is in the open position. Technicians value when their customer can inform them what the board is doing before they show up on site.

In summary

Zone controls are no longer “your dad’s old relay boards.” They can handle an entire hydronic system. They can integrate seamlessly with onboard boiler controls. They provide the performance contractors desire in an attractive package that complements a well earned professional reputation. The most technologically advanced, flexible zone controls with the latest features can save a professional a great deal of time, simplify maintenance needs and give the customer the ultimate in comfort.

Dan Firkus is an applications engineer for Caleffi North America.